Are you struggling to find a reliable factory in China? Choosing the wrong one can lead to delays, poor quality, and lost revenue. However, finding a trustworthy factory ensures consistent quality, on-time deliveries, and better pricing. In this guide, you’ll learn how to identify, vet, and select the best factories in China to give your business a competitive edge.

Start with a Clear Understanding of Your Needs

Do You Know Exactly What You Need from Your Factory?

Before you even start looking for factories in China, you need to be crystal clear on what you’re asking for. Factories can’t deliver the right product if your requirements are vague. Are you certain about your product’s material quality, design, and compliance standards? Without these specifics, you risk getting products that don’t meet your expectations. Here’s what you need to define before reaching out to any factory:

- Material quality: What exact materials will be used?

- Design details: Dimensions, colors, and any custom features.

- Compliance standards: Certifications needed for your market (e.g., CE, RoHS).

- MOQ (Minimum Order Quantity): The minimum number of units you need to order.

Each of these points helps the factory understand what you want, which in turn improves the quality and reduces production errors.

Factory Type Matters: OEM vs. ODM

Not all factories are the same, and choosing the right type can save you time and money. Are you looking for OEM (Original Equipment Manufacturer) or ODM (Original Design Manufacturer)? Here’s a quick comparison to help you decide:

| Factory Type | Customization Level | Cost | Time to Market | Best For |

|---|---|---|---|---|

| OEM | High (custom designs) | Higher | Longer | Unique products |

| ODM | Low (pre-designed) | Lower | Faster | Generic products |

If you need something fully custom, an OEM is the way to go. But if you want to bring a product to market quickly with fewer customization needs, ODM might be a better choice.

Researching Factories: Tools and Platforms to Use

What Are the Best Platforms to Find Reliable Factories in China?

Finding the best factory starts with using the right tools. China has a massive manufacturing base, and navigating it can feel overwhelming. Luckily, several platforms can help you connect with the right factory. Here are some of the top platforms to consider:

- Alibaba: One of the largest B2B platforms in the world. You can find thousands of suppliers, but it’s crucial to filter out the bad ones.

- Pros: Large variety of suppliers, buyer protection, international-friendly.

- Cons: Many trading companies posing as factories, high competition.

- 1688: A China-specific version of Alibaba, often used by local businesses. Prices here are typically lower, but it’s less foreigner-friendly.

- Pros: Lower prices, access to domestic-only factories.

- Cons: No English interface, payment issues for non-Chinese buyers.

- Global Sources: A trusted platform for connecting with verified manufacturers. They focus more on quality than quantity, making it easier to find reliable partners.

- Pros: Verified suppliers, stricter screening process.

- Cons: Smaller pool of suppliers compared to Alibaba.

Each of these platforms has its strengths and weaknesses. If you’re sourcing from China for the first time, Alibaba is a safe bet, but Global Sources might be better if you prioritize quality over variety.

Alternative Methods: Trade Fairs and In-Person Visits

Besides online platforms, nothing beats meeting manufacturers in person. Trade fairs are an excellent way to connect directly with factories, see product samples, and build relationships. Here are two must-visit fairs in China:

- Canton Fair: China’s largest and most famous trade fair. It’s held in Guangzhou and covers nearly every industry.

- Yiwu Market: Known for small commodities and wholesale items, this is the place to go for high-volume, low-cost products.

These events are ideal for finding niche manufacturers, inspecting product quality up close, and negotiating face-to-face. Plus, visiting a factory in person can give you a better feel for their operations and reliability.

How to Vet Factories in China

Are You Confident the Factory You Chose is Reliable?

Finding a factory is only the first step. Before you move forward, it’s crucial to vet the factory to ensure they can deliver consistent quality and meet your production needs. Without proper vetting, you risk running into delays, receiving defective products, or worse—working with a fraudulent supplier. So, how do you conduct a thorough background check?

Perform a Thorough Background Check

Asking for the right documents and certifications is a critical part of the vetting process. These documents not only verify the factory’s legitimacy but also ensure they meet industry standards. Here’s what you should request:

- Business license: Confirms the factory is legally registered.

- ISO certifications: Ensures they meet international quality standards.

- Client testimonials: Ask for references or case studies from previous clients.

These documents provide a strong starting point for verifying if a factory is trustworthy and capable of meeting your expectations.

Conducting Factory Audits

A factory audit is one of the most effective ways to assess a supplier’s capabilities. If possible, you or a trusted third party should visit the factory to check the production environment and ensure they meet your standards. The factory audit process typically includes four key steps:

- Pre-audit preparation: Set goals for what you need to inspect (quality control, production capacity, etc.).

- On-site inspection: Review equipment, worker conditions, and quality control processes.

- Reporting: Document the findings and evaluate whether the factory meets your needs.

- Decision-making: Based on the audit results, decide if the factory is suitable.

A simple flowchart diagram can visually summarize these steps, making it easier for you to follow and organize your vetting process.

Red Flags to Watch Out For

Even with solid paperwork, some factories can still raise red flags. Be on the lookout for signs that a factory might not be as reliable as they claim:

- Inconsistent communication: Slow responses or vague answers could indicate they are unreliable.

- Refusal to provide certifications: Any hesitation to share official documents is a major warning sign.

- Limited production capacity: If they can’t handle your volume, it’s likely they’ll struggle to meet deadlines.

By identifying these red flags early, you can avoid costly mistakes and ensure you’re working with a reliable partner.

Key Metrics to Evaluate When Choosing a Factory

Can This Factory Meet Your Production Demands?

One of the most important questions to ask is: can the factory handle your order volume and meet deadlines? Assessing a factory’s production capacity ensures they can scale with your business, avoiding delays and bottlenecks. The last thing you want is to commit to a factory that can’t keep up with your needs. Let’s look at the key metrics you need to evaluate.

Production Capacity

To match a factory’s production capacity with your business goals, it’s essential to compare their capabilities with your requirements. Consider these three critical factors:

| Metric | What to Check | Why It Matters |

|---|---|---|

| Daily output | Units produced per day | Ensures the factory can meet demand |

| Lead times | Time to complete an order | Impacts your ability to meet deadlines |

| Maximum production capability | Highest volume they can produce | Determines if they can scale as your business grows |

By aligning their output and lead times with your order volume, you can avoid production delays and ensure smooth operations.

Quality Control Systems

No matter how great the production capacity, quality control is non-negotiable. Without proper systems in place, you could end up with defective products that damage your brand. Here are the essential quality control steps a factory should follow:

- In-house quality checks: Regular inspections on the production line.

- Third-party inspections: Independent checks to verify product quality.

- Sample testing: Testing random product samples before full-scale production.

Factories with a robust quality control system will ensure your products meet the highest standards and avoid costly returns or complaints.

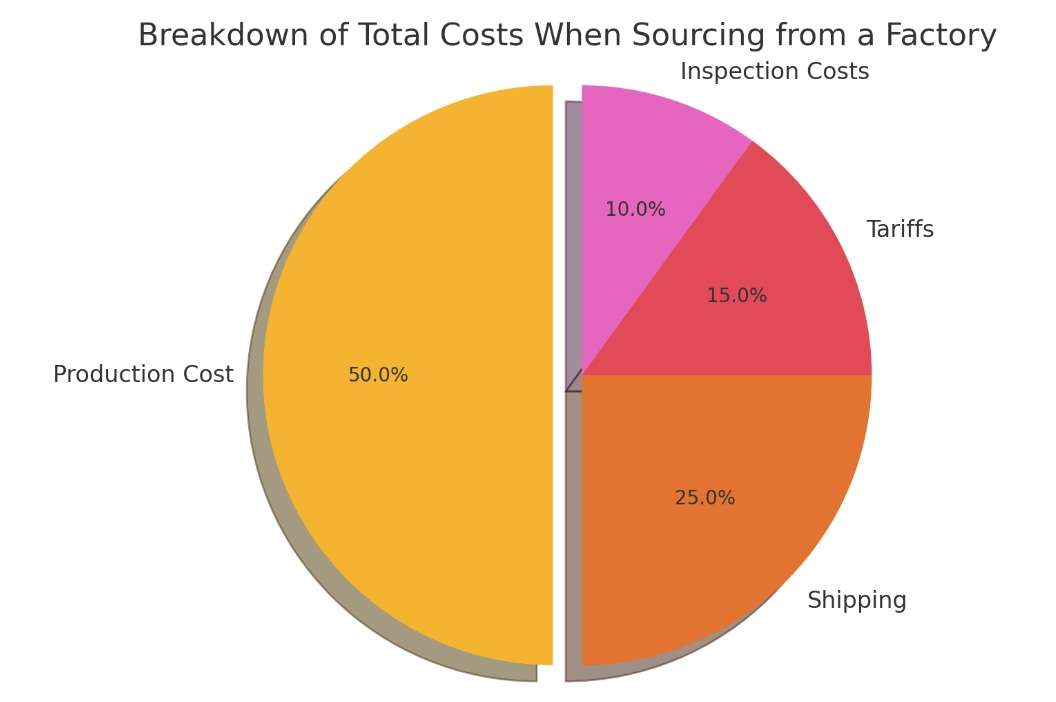

Pricing and Total Cost of Ownership

While price is an important factor, you need to consider the total cost of ownership when working with a factory. It’s easy to focus on production costs, but other factors like shipping, tariffs, and inspection costs can quickly add up. A pie chart showing these components can provide a clear view of where your money is going:

By understanding the full cost picture, you can make better decisions and avoid hidden costs that impact your profit margins.

Building a Strong Partnership with Your Factory

Is Your Communication with the Factory Helping or Hurting Your Partnership?

Effective communication is the foundation of any strong relationship, and this is especially true when working with a factory in China. Without clear, consistent communication, misunderstandings can arise, leading to production delays, quality issues, or even damaged relationships. The good news? Maintaining a productive dialogue with your factory doesn’t have to be complicated.

Communication is Key

To keep things running smoothly, you need to establish open lines of communication and set clear expectations from the start. Here are some key tips to improve communication with your factory:

- Use WeChat for real-time messaging: This app is widely used in China and allows for quick communication, voice calls, and sharing of images.

- Set clear expectations for regular updates: Specify how often you need progress reports and what information should be included (production stages, timelines, potential issues).

- Establish a point-of-contact at the factory: This will ensure that any questions or problems can be resolved quickly without miscommunication between multiple parties.

Strong communication will help avoid costly errors and keep your project on track, while also building a more collaborative relationship with your supplier.

Building Trust with Long-term Partnerships

Building a strong partnership isn’t just about the transaction—it’s about establishing trust and developing a long-term relationship that benefits both sides. In Chinese business culture, long-term relationships are often valued over short-term gains. By showing loyalty and reliability, you can secure better prices, higher priority, and even customized services as the relationship grows.

Building a strong partnership isn’t just about the transaction—it’s about establishing trust and developing a long-term relationship that benefits both sides. In Chinese business culture, long-term relationships are often valued over short-term gains. By showing loyalty and reliability, you can secure better prices, higher priority, and even customized services as the relationship grows.

Common Pitfalls and How to Avoid Them

Are You Making These Costly Mistakes When Choosing a Factory?

When sourcing factories in China, it’s easy to fall into common traps that can cost you time, money, and even your business’s reputation. Many businesses overlook critical details that end up hurting them later on. To avoid these pitfalls, it’s crucial to learn from others’ mistakes.

Skipping Due Diligence

Failing to perform due diligence on a factory is a recipe for disaster. Without proper vetting, you could face serious consequences that are difficult to fix later on. Here’s what can happen if you skip this crucial step:

- Delays in production: Factories may overpromise and underdeliver, leading to missed deadlines.

- Receiving sub-standard products: Without checking for quality control processes, you risk receiving products that don’t meet your specifications.

- Loss of investment due to fraud: Some factories may not be legitimate, and you could lose your deposit or entire payment.

By conducting a thorough background check and factory audit, you can minimize these risks and ensure you’re working with a reliable partner.

Only Focusing on Price

Choosing a factory based solely on price is another major pitfall. While it’s tempting to go with the lowest quote, this often leads to poor quality and hidden costs down the line. Here’s a comparison of what you might encounter at different price points:

| Factory Type | Price | Quality | Reliability |

|---|---|---|---|

| Low-cost factory | Lowest | Poor quality control | Frequent delays, high risk |

| Mid-range factory | Moderate | Balanced quality and cost | Reliable production |

| High-end factory | Highest | Premium services and quality | High reliability, top-tier quality |

Focusing too much on price can lead to quality issues, delayed timelines, or even more expenses to fix the mistakes. Instead, aim for a balance between cost and quality to get the best value.

Lack of Contractual Clarity

A poorly written or unclear contract can lead to disputes and confusion during production. To protect yourself, your contract should include several key clauses that set clear expectations for both parties. Make sure to cover these points:

- Delivery times: Specify exact deadlines to avoid delays.

- Penalties for delays: Set consequences if the factory fails to meet delivery dates.

- Warranty terms: Define how defective products will be handled.

- Intellectual property rights: Protect your designs and product concepts from being copied or sold to other clients.

By ensuring your contract is clear and comprehensive, you can avoid misunderstandings and hold the factory accountable if something goes wrong.

Advanced Tips for Finding the Best Factories in China

Are You Using All the Resources Available to Find the Perfect Factory?

Finding the best factories in China often requires going beyond basic platforms like Alibaba. To really fine-tune your sourcing strategy, you need to tap into advanced methods that provide better insights and access to niche markets. These methods can save you time, improve the quality of your products, and give you access to factories that might otherwise be off your radar.

Use of Sourcing Agents for Niche Products

If you’re looking for specialized factories that aren’t easily found on large platforms, working with a sourcing agent can be a game-changer. Sourcing agents are professionals with local expertise who know how to navigate the complex landscape of Chinese manufacturing. Here are the key benefits of working with sourcing agents:

- Access to smaller, specialized factories: Many niche manufacturers don’t advertise on major platforms, but sourcing agents can connect you directly with them.

- Time saved in factory vetting: Agents often have a pre-vetted network of factories, saving you the hassle of verifying each one yourself.

- Local expertise: With their understanding of Chinese business practices and language, sourcing agents can negotiate better deals and avoid potential pitfalls.

By leveraging the knowledge and connections of a sourcing agent, you can find high-quality factories faster and with less risk.

Factory Tours: When to Visit and What to Look For

There’s no better way to vet a factory than by visiting it in person. A factory tour allows you to see firsthand how the factory operates and whether it can meet your quality standards. If you have the opportunity, a tour can provide invaluable insights that simply aren’t possible through remote communication.

When visiting a factory, pay attention to the following:

- Factory cleanliness: A clean environment is often a sign of well-organized management and attention to detail.

- Organization of the production line: Well-organized production lines usually mean more efficient manufacturing and higher quality control.

- Employee working conditions: Ensure the factory treats its workers well, as poor working conditions can lead to higher turnover and inconsistent production.

Consider adding an image of a factory tour with inspectors evaluating machinery and product lines. This helps visualize the importance of seeing the production process up close.

Final Steps to Secure the Best Factory Partnership

Are You Ready to Find the Best Factory for Your Business?

Now that you know the key steps to finding and vetting factories in China, you’re ready to make informed decisions that will protect your business and help you scale efficiently. Let’s quickly recap the essential steps you should follow:

- Know your product requirements: Be clear on materials, design, and compliance standards.

- Research factories on trusted platforms: Use Alibaba, Global Sources, and sourcing agents to find reliable suppliers.

- Vet each factory thoroughly: Request business licenses, certifications, and perform factory audits.

- Prioritize quality over price: A balance between cost and quality will lead to better long-term results.

By following these steps, you’ll avoid common pitfalls, save time, and ensure you’re working with a trustworthy partner that can grow with your business.

Bonus Section: Resources for First-Time Sourcing

Here are some trusted third-party services and resources to help you with factory vetting and quality control:

- AsiaInspection (QIMA): A trusted third-party inspection service for factory audits and quality control.

- SGS: Provides inspection, verification, testing, and certification services.

- Audit templates: Downloadable factory audit checklists for your own inspections.

- Links to sourcing platforms: Direct links to Alibaba, Global Sources, and Made-in-China.

These resources can provide extra assurance and streamline the process of finding the best factories in China.

Ready to take the next step? Contact us to get personalized advice on sourcing factories in China, or download our free audit checklist to start vetting suppliers today.

FAQ: Finding the Best Factories in China

Why should I source factories in China?

China offers the world’s largest and most diverse manufacturing sector, making it an ideal destination for businesses looking for a broad range of products at competitive prices. The country also has a wealth of specialized factories with decades of experience in mass production, allowing you to access expertise and scale quickly.

What are the best platforms to find factories in China?

Alibaba is one of the top platforms for international buyers due to its wide range of suppliers and global reach. 1688 caters primarily to local Chinese businesses and offers lower prices, though it’s more challenging for foreign buyers. Global Sources focuses on verified suppliers, making it a great choice for businesses that prioritize quality over quantity.

How can I verify if a factory is legitimate?

To verify a factory's legitimacy, ask for essential documents such as a business license to ensure they are legally registered, ISO certifications to confirm they meet international standards, and client testimonials from past buyers to assess reliability. Conducting a factory audit or using a third-party inspection service is also an effective way to ensure they meet your standards.

What are the red flags to watch out for when vetting a factory?

Some common red flags include inconsistent communication, where the factory is slow or unclear in their responses, and a refusal to provide certifications, which could indicate they are hiding something. Additionally, factories with limited production capacity may struggle to meet your order volume, especially if you plan to scale up.

Should I focus solely on price when choosing a factory?

Focusing only on price can lead to poor-quality products, unexpected delays, and hidden costs down the line. While price is important, it’s essential to strike a balance between cost, quality, and reliability to ensure you get the best overall value for your business.

What are the benefits of using a sourcing agent?

Sourcing agents provide access to smaller, specialized factories that may not be listed on major platforms. They also save you time by pre-vetting suppliers and handling much of the legwork, while their local expertise helps in negotiating better deals and managing communication with factories.

When is the best time to visit a factory in person?

The best time to visit a factory is after you’ve shortlisted potential suppliers. Visiting allows you to verify their production capabilities, inspect their quality control systems, and assess working conditions. A face-to-face visit also helps strengthen your relationship with the factory.

What should be included in a factory contract?

A clear factory contract should include specific delivery times to avoid delays, penalties for missed deadlines, and warranty terms outlining how defects or quality issues will be handled. It’s also crucial to include intellectual property protections to ensure your designs and product concepts are safe from being copied or sold to others.